Product information

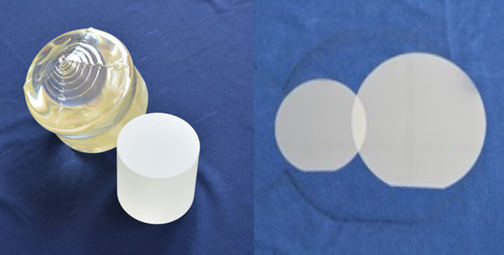

Synthetic Quartz Crystals

Synthetic quartz are materials used to grow synthetic quartz crystals and serve as substrates for crystal growth.

Synthetic quartz crystals are made from high-purity natural crystals and cut in a specific direction.

It is important to use high quality synthetic quartz crystals because they have a significant influence on the physical properties and quality of the synthetic quartz crystals being grown.

In addition, because the shape, size, and precision of synthetic quartz crystals vary depending on the growing method, it is necessary to select appropriate quartz crystals according to the type of synthetic quartz crystal customers require.

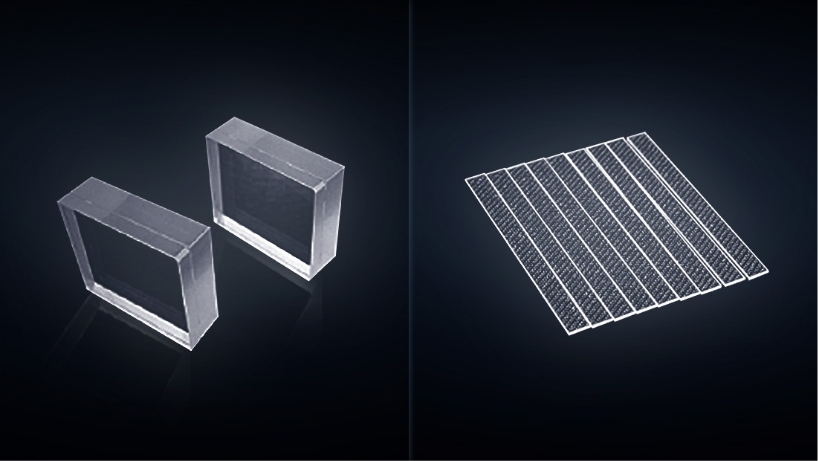

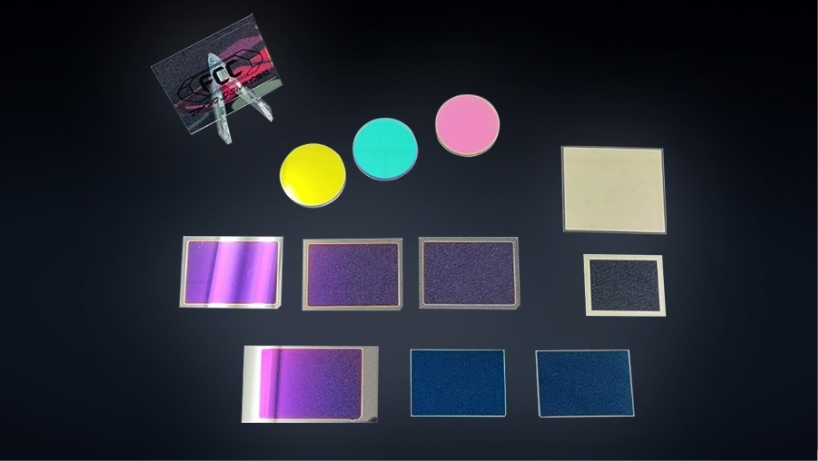

Optical Low-Pass Filters

OLPFs are designed to improve image quality by cutting high-frequency noise and high-frequency images.

The filters are transparent to low frequency information while absorbing high frequency information,resulting in a smooth and beautiful image.

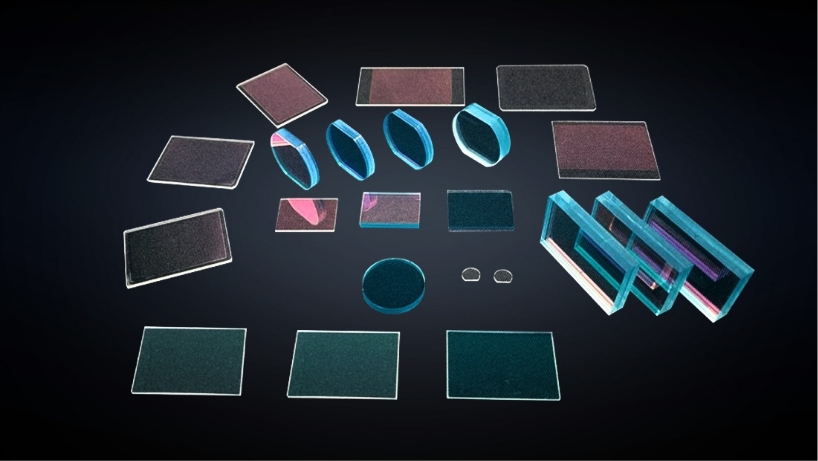

Waveplates

Quartz waveplates are a type of optical element used to control the polarization of electromagnetic

waves. Quartz waveplates are mainly used in areas such as polarizing microscopes, polarizing filters,

and laser optics. Quartz waveplates are used as polarizers or filters, some of which can convert light

in an elliptically polarized state to a circularly polarized state.

Laser optics also uses quartz waveplates to control the polarization direction of light, creating

optically active materials with different reflectivity and transmittance depending on the polarization

direction of light.

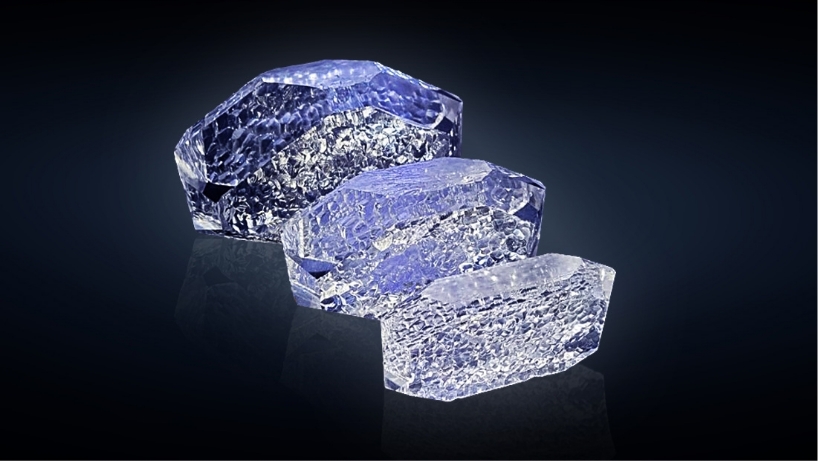

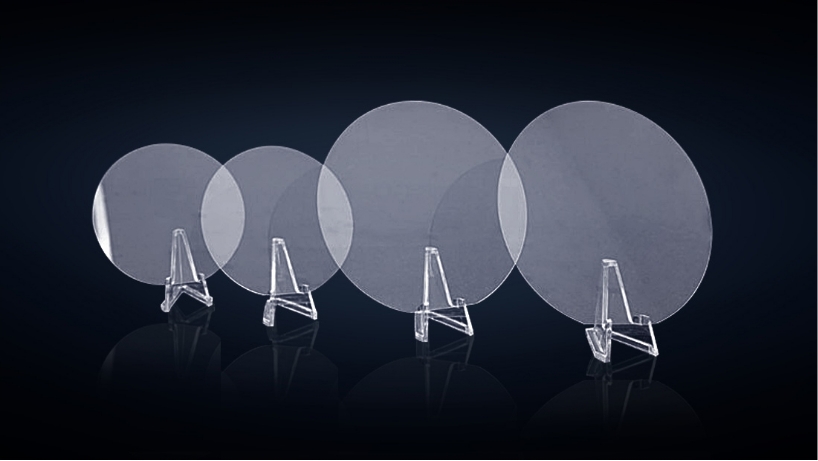

Wafers

Quartz wafers are a type of wafer, a thin semiconductor plate, used in the manufacture of electronic

devices and integrated circuits.

Quartz crystal wafers are mainly used in areas such as wireless communications and sensors.

For example, crystal wafers are used to make clock generators, filters, and accelerometers in cell

phones and smartphones.

Quartz wafers have become indispensable components in modern electronic devices due to their

high reliability and stability.

Developed Products

We have also focused on various types of development, taking advantage of our integrated

production system. We will keep you updated on the technologies of products we are currently

working on. If you are interested, please contact us through our inquiries page.

Film Formation Technology

Film formation technology refers to the technology used to form a film on the surface of a material.

The film formation must facilitate the reaction that converts the substance into a membrane.

Thus, film formation technology has physical and chemical approaches.

The physical technology includes vacuum deposition, sputtering, and plasma processing.

These technologies use evaporation, sputtering, or plasma reactions to deposit materials on surfaces,

resulting in the formation of a film.