Optical Low-Pass Filters

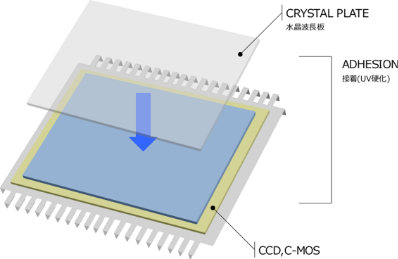

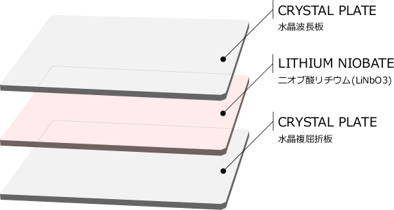

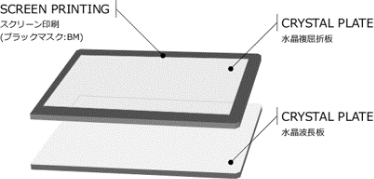

Illustration-1

As the demand for high-quality images continues to grow, OLPFs have the potential to improve image quality in a wide range of consumer electronics, including digital

cameras, smartphones, and tablets.

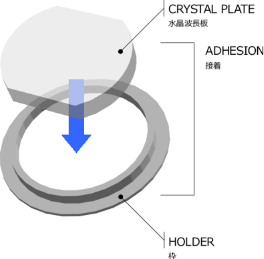

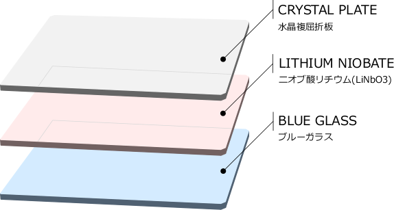

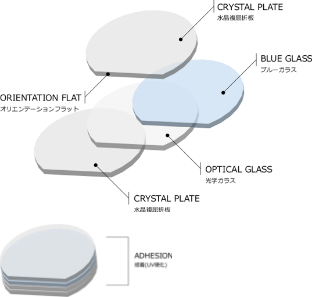

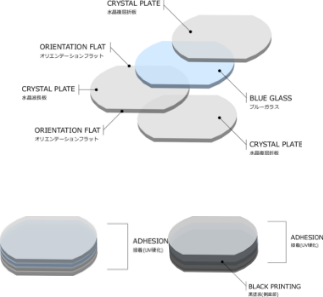

Illustration-2

OLPFs have the potential to improve the image quality of medical imaging devices, such as computed tomography (CT) scanners, magnetic resonance imaging (MRI) systems,

and ultrasound equipment.

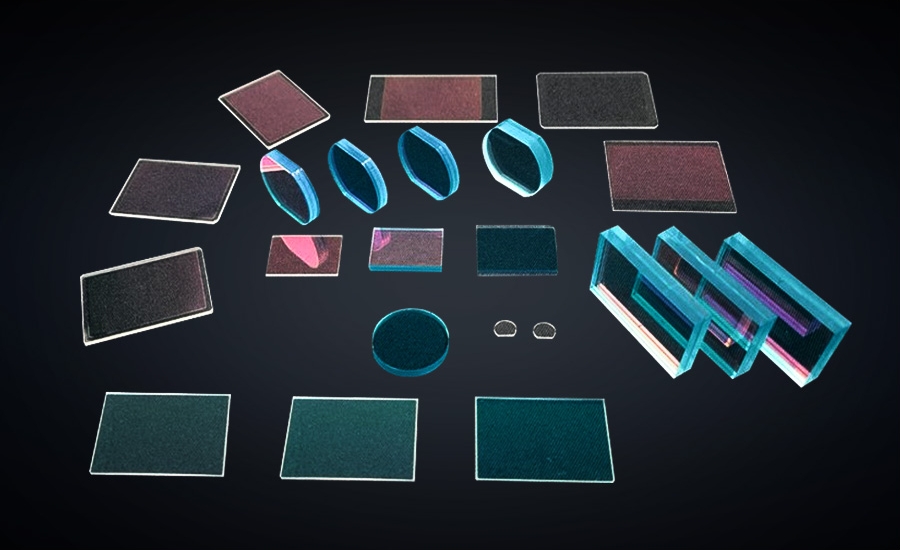

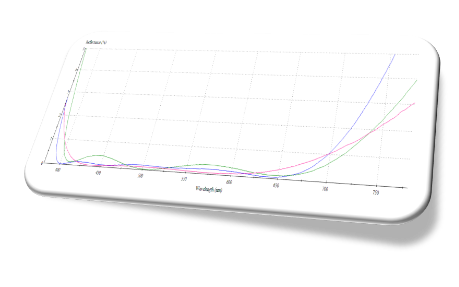

Graph of Typical Spectral Characteristics

Vacuum evaporation involves placing materials in a vacuum and evaporating them by creating a high-temperature environment. The evaporated material adsorbs and forms a thin layer on the surface in the vacuum. This process takes place in a vacuum environment, eliminating interference from air and other substances.

Vacuum evaporation offers several advantages, such as high-precision film formation, fast deposition speed, and high quality crystal formation. This technology is used in many areas, including semiconductor device manufacturing, optical device manufacturing, electronic device protection, and surface treatment.

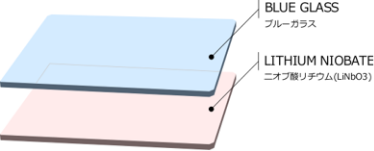

What else we can do: Adhesive Techniques

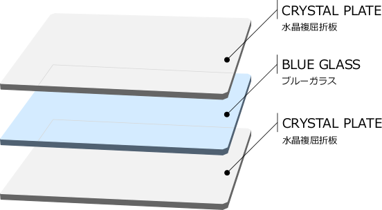

This and that of Optical Low-Pass Filter (OLPF)

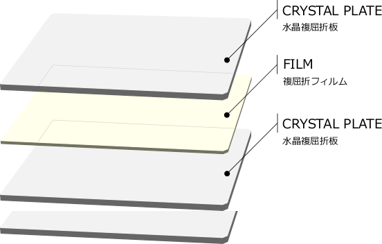

The filter removes non-existent moiré patterns by taking advantage of birefringence, a property of

quartz crystal.

In a digital camera with light-receiving elements (pixels) arranged in a regular pattern, the superposition of the resolution pattern of a subject with a regular pattern and the spacing between the light-receiving elements can cause a pattern that does not exist in reality, called 'moire'.