Film Formation Technology

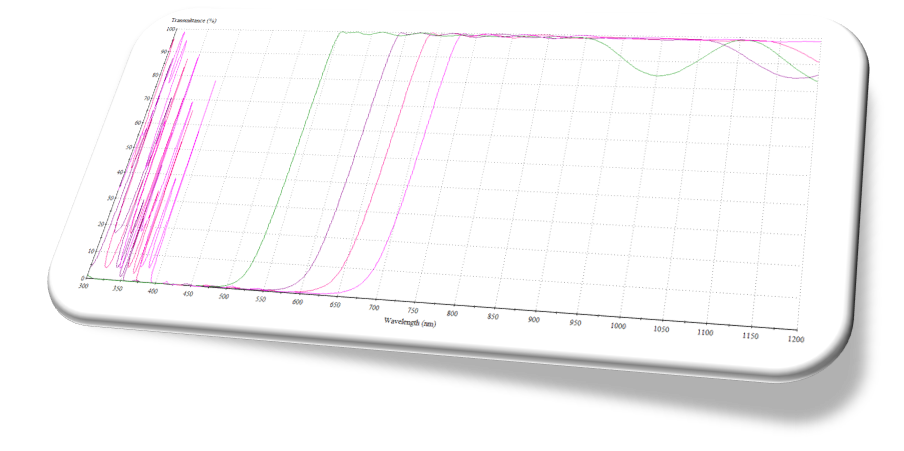

Anti-reflection (AR) coatings

This coating reduces reflectance and increases transmittance.

It is used for eyeglass lenses, TV and computer screens, camera lenses, etc.

- ・Film deposition method: Vacuum evaporation

- ・Film deposition conditions: Ion-assisted deposition/ non-ion-assisted deposition

- ・Layer:3L~

- ・Material:TiO2/H4/SiO2/Al2O3/ZrO2/MgF2

- ・Substrate:Optical glass, Synthetic quartz crystal, Blue glass

- ・Incident Angle:0°、10°、30°

The desired wavelength range and transmittance can be adjusted separately.

※ The figure includes a design value.

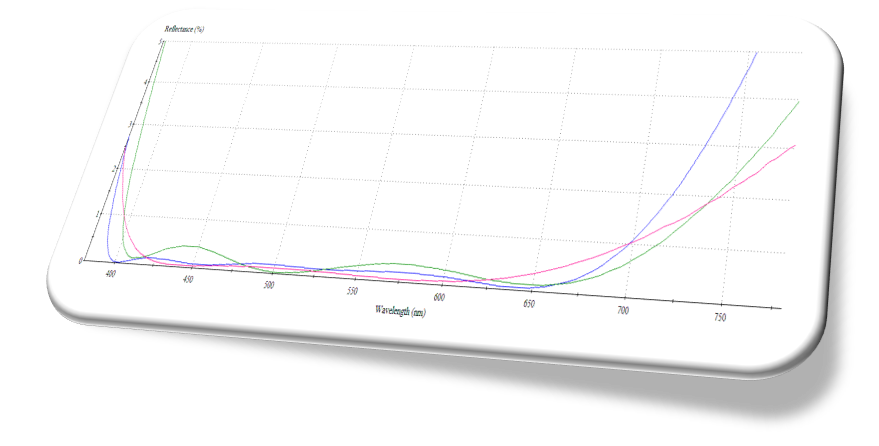

Broadband Antireflection (AR) Film Coating

This coating reduces reflectance and increases transmittance.

The band width is designed to be wider than that of a regular AR coat.

It is used for eyeglass lenses, TV and computer screens, camera lenses, etc.

- ・Film deposition method: Vacuum evaporation

- ・Film deposition conditions: Ion-assisted deposition/ non-ion-assisted deposition

- ・Layer:8L~

- ・Material:TiO2/H4/SiO2/Al2O3/ZrO2/MgF2

- ・Substrate:Optical glass, Synthetic quartz crystal, Blue glass

- ・Incident Angle:0°、10°、30°

The desired wavelength range and transmittance can be adjusted separately.

※ The figure includes a design value.

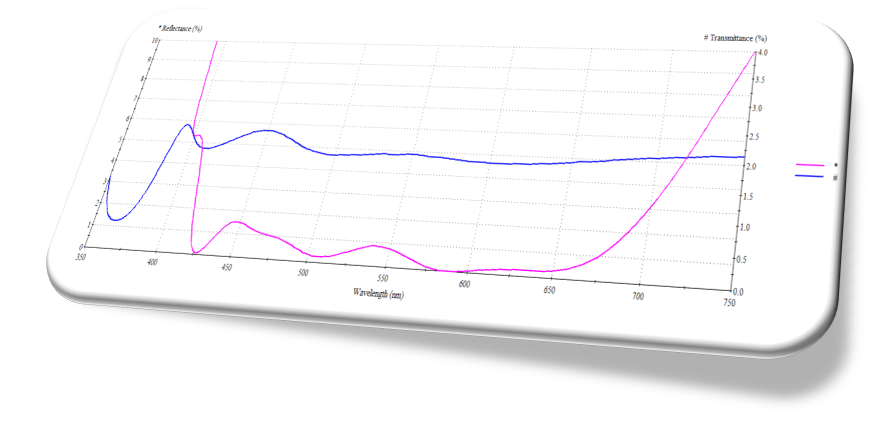

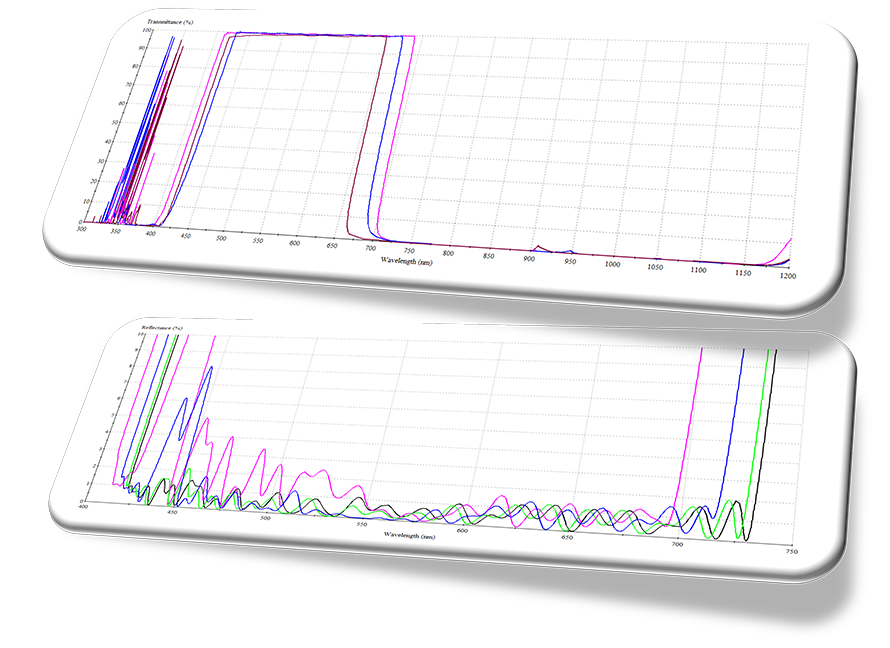

ND Filter

The black filter limits the amount of light that passes through the lens without affecting color.

It is used for camera lenses.

- ・Film deposition method: Vacuum evaporation

- ・Film deposition conditions: Ion-assisted deposition/ non-ion-assisted deposition

- ・Layer:20L~

- ・Material:TiO2/SiO2/Cr

- ・Substrate: Optical glass, Synthetic quartz crystal

- ・Incident Angle:0°

The desired wavelength range and transmittance can be adjusted separately.

※ The figure includes a design value.

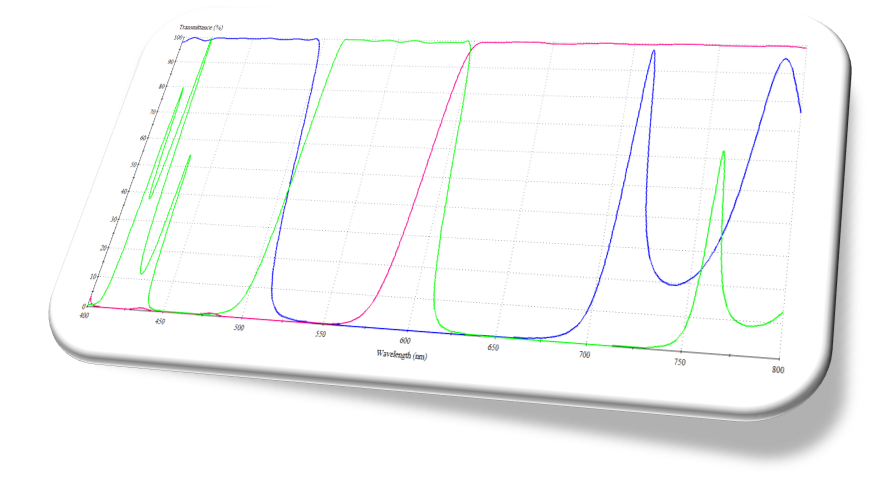

Dichroic Filter

This coating transmits and reflects only a specific wavelength range to produce the color of each wavelength range.

It is used for color printers and lighting equipment.

- ・Film deposition method: Vacuum evaporation

- ・Film deposition conditions: Ion-assisted deposition/ non-ion-assisted deposition

- ・Layer:30L~

- ・Material:TiO2/SiO2

- ・Substrate:Optical glass, Synthetic quartz crystal, Blue glass

- ・Incident Angle:0°、10°、30°

The desired wavelength range and transmittance can be adjusted separately.

※ The figure includes a design value.

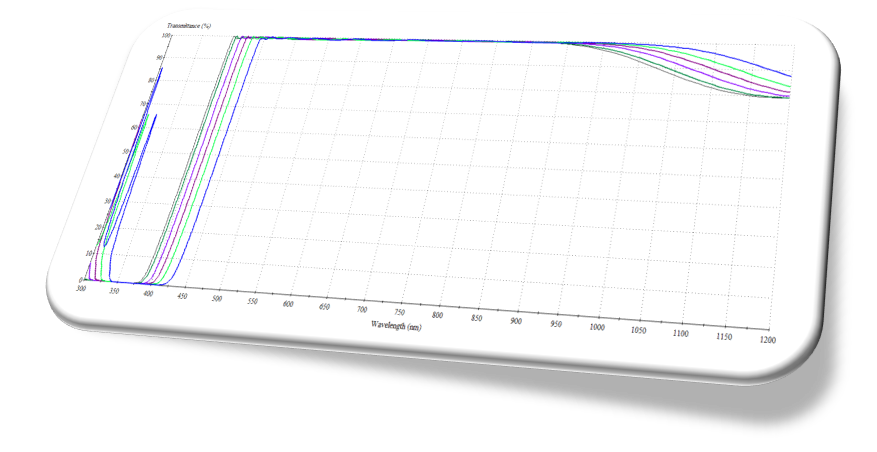

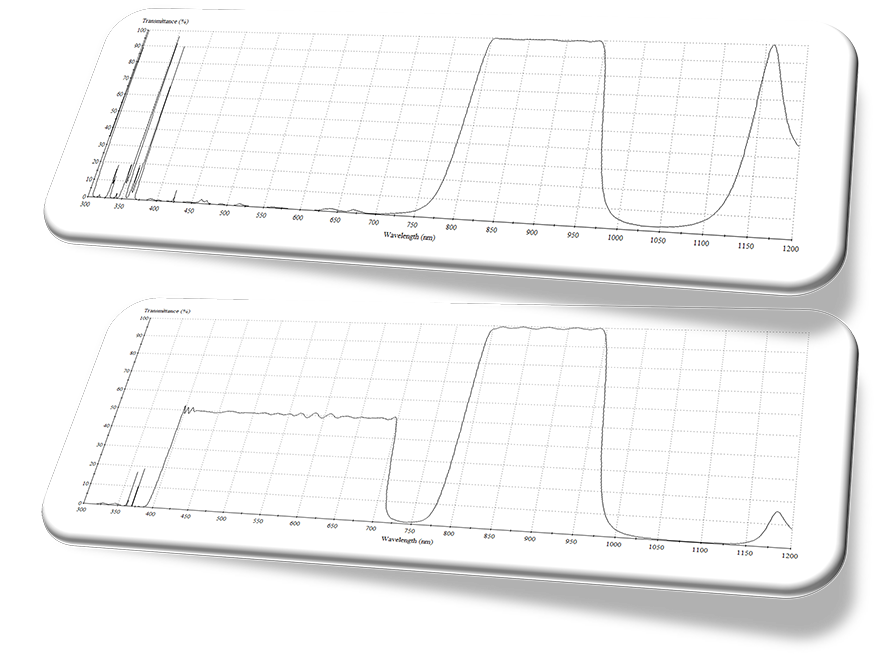

UV-cut Coating

This coating blocks the near-ultraviolet region.

It is used for camera lenses, LCD projectors, and lamps.

- ・Film deposition method: Vacuum evaporation

- ・Film deposition conditions: Ion-assisted deposition/ non-ion-assisted deposition

- ・Layer:10L~

- ・Material:TiO2/SiO2

- ・Substrate:Optical glass, Synthetic quartz crystal, Blue glass

- ・Incident Angle:0°、10°、30°

The desired wavelength range and transmittance can be adjusted separately.

※ The figure includes a design value.

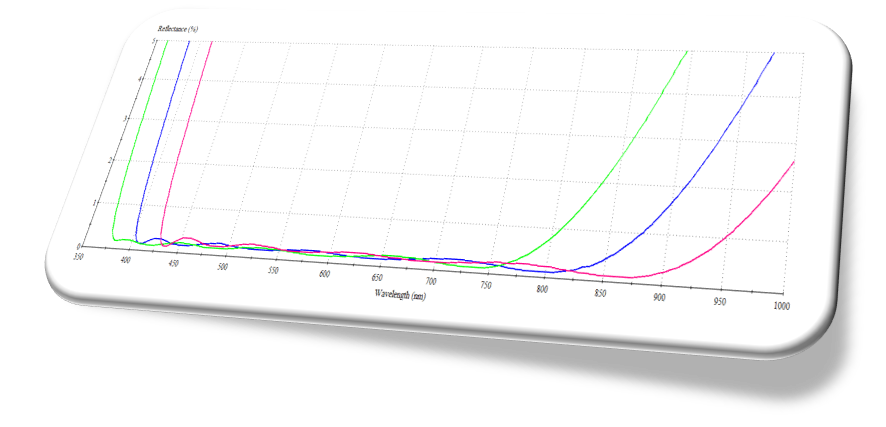

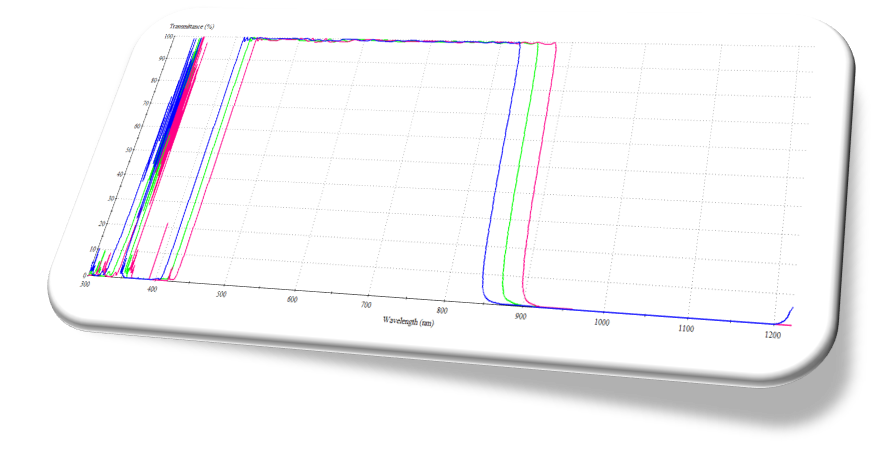

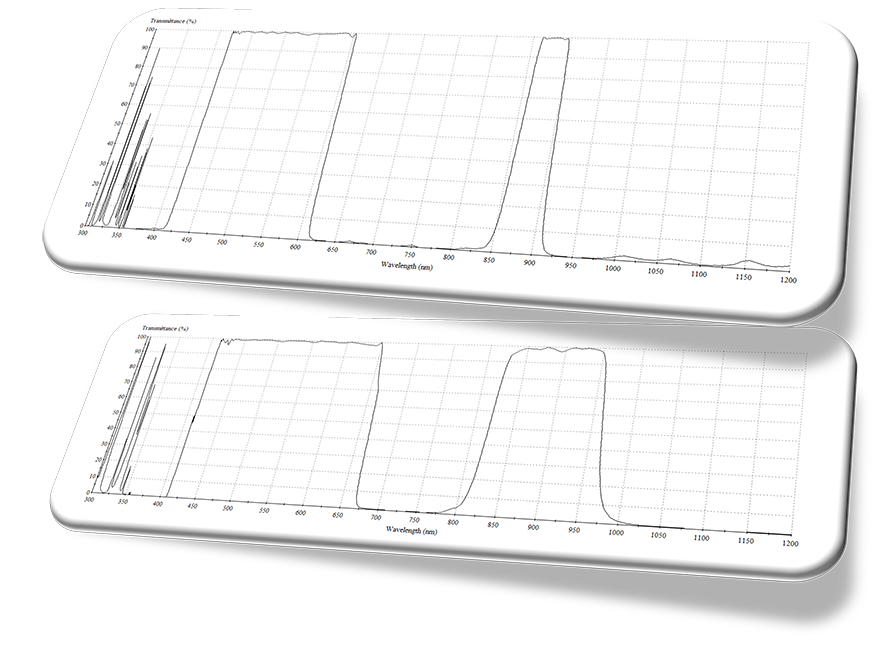

UV-IR cut Coating

This coating blocks the near-ultraviolet and near-infrared regions.

It is used in cameras, smartphones, drones, LCD projectors, professional movies, medical cameras, etc.

- ・Film deposition method: Vacuum evaporation

- ・Film deposition conditions: Ion-assisted deposition/ non-ion-assisted deposition

- ・Layer:30L~

- ・Material:TiO2/SiO2/H4/ITO/TNO

- ・Substrate:Optical glass, Synthetic quartz crystal, Blue glass

- ・Incident Angle:0°、10°、30°

The desired wavelength range and band width can be adjusted separately.

It can also be used for incident angle dependence.

※ The figure includes a design value.

Broadband UV-IR cut Coating

This coating blocks the near-ultraviolet and near-infrared regions.

It is used in cameras, smartphones, drones, LCD projectors, professional movies, medical cameras, etc.

- ・Film deposition method: Vacuum evaporation

- ・Film deposition conditions: Ion-assisted deposition/ non-ion-assisted deposition

- ・Layer:50L~

- ・Material:TiO2/SiO2/H4/ITO/TNO

- ・Substrate:Optical glass, Synthetic quartz crystal, Blue glass

- ・Incident Angle:0°、10°、30°

The desired wavelength range and band width can be adjusted separately.

※ The figure includes a design value.

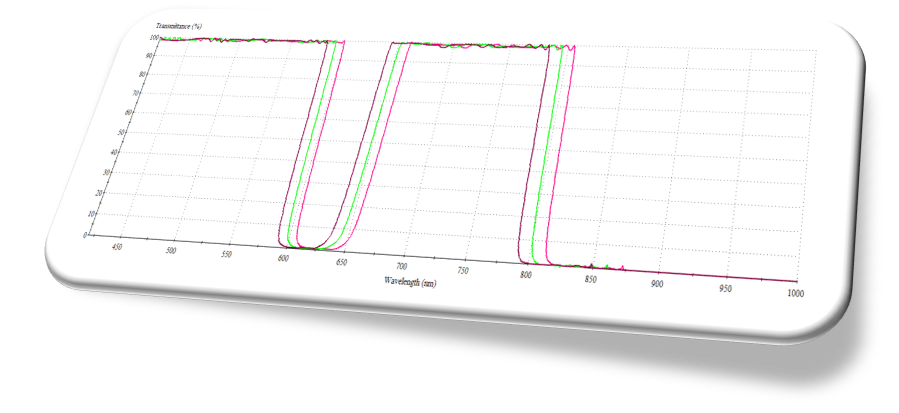

Bandpass Filter

This coating transmits only a certain wavelength range.

It is used in measuring and analysis equipment, proximity switches, optical communication, lighting equipment, etc.

- ・Film deposition method: Vacuum evaporation

- ・Film deposition conditions: Ion-assisted deposition/ non-ion-assisted deposition

- ・Layer:50L~

- ・Material:TiO2/H4/SiO2/Ta2O5

- ・Substrate: Optical glass, Synthetic quartz crystal

- ・Incident Angle:0°

The desired wavelength range and transmittance can be adjusted separately.

※ The figure includes a design value.

Cold Mirror Coat

This mirror coat transmits near-infrared rays or heat rays, which raise the temperature of the irradiated object, and efficiently reflects visible light rays.

It is used in LCD projectors, operating tables, lighting, etc.

- ・Film deposition method: Vacuum evaporation

- ・Film deposition conditions: Ion-assisted deposition/ non-ion-assisted deposition

- ・Layer:40L~

- ・Material:TiO2/H4/SiO2

- ・Substrate:Optical glass, Synthetic quartz crystal

- ・Incident Angle:0°

The desired wavelength range and transmittance can be adjusted separately.

※ The figure includes a design value.

Near-Infrared Transmissive Coating

This filter absorbs visible light and transmits near-infrared light.

It is used for sensors that require infrared light. It can also be used for incident angle dependency.

- ・Film deposition method: Vacuum evaporation

- ・Film deposition conditions: Ion-assisted deposition/ non-ion-assisted deposition

- ・Layer:30L~

- ・Material:TiO2/SiO2

- ・Substrate: Optical glass, Synthetic quartz crystal

- ・Incident Angle:0°

The desired wavelength range and transmittance can be adjusted separately.

※ The figure includes a design value.

Edge/Notch Filter

An edge filter is a filter that abruptly changes between transparent and opaque bands.

It is used for various sensors and projectors, etc.

- ・Film deposition method: Vacuum evaporation

- ・Film deposition conditions: Ion-assisted deposition/ non-ion-assisted deposition

- ・Layer:70L~

- ・Material:TiO2/SiO2

- ・Substrate:Optical glass, Synthetic quartz crystal

- ・Incident Angle:0°

The desired wavelength range and transmittance can be adjusted separately.

Depending on the number of layers, there may be some products our vacuum evaporation machine cannot support. In such cases, we can consider the possibility at one of our overseas factories.

※ The figure includes a design value.

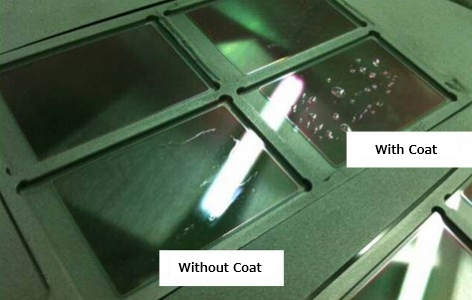

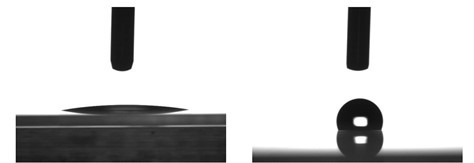

Fluorine Coating (Water Repellent Film)

The coating on the top surface of each layer can provide water repellency.

It repels moisture, dirt, grease, etc.

- ・Film-deposition method: Vacuum evaporation

- ・Film-deposition condition: Non-heating or resistance heating method

- ・Layer:ー

- ・Material:OF-SR、WR4

- ・Substrate:Optical glass, Synthetic quartz crystal

- ・Incident Angle:ー

- ・Contact angle : 80°~

Conductive Film

This coating reduces surface resistivity.

The effect of releasing electricity prevents the adhesion of stains caused by electrification.

- ・Film-deposition method: Vacuum evaporation

- ・Film deposition conditions: Ion-assisted deposition/ non-ion-assisted deposition

- ・Layer:3L~

- ・Material:ITO、TNO

- ・Substrate:Optical glass, Synthetic quartz crystal

- ・Incident Angle:10°、20°、30°

- ・Contact angle : 80°~

The desired wavelength range and band width can be adjusted separately.